Box dimensions are a crucial piece of information when working on a custom packaging project. Dimensions have an impact on what materials are used, finishing & embellishment options, production costs, shipping, etc.

There are three main dimensions by which boxes are measured: length, width and depth. Here we will go through the most important considerations for measuring your custom box.

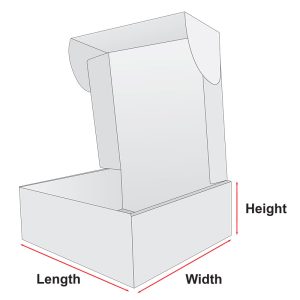

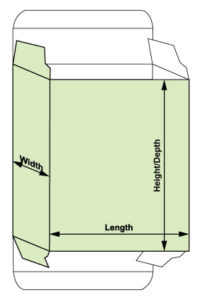

How-to Measure a Box

Set the box down with the top/loading-side facing up and the front panel facing you

Length: take the measurement from left to right

Width: measure the side panels from front to back

Depth: take the measurement from top to bottom (excluding closure flaps)

Should I measure the inside of the box, or the outside?

Internal dimensions (usable space) are preferred as it ensures the box will fit your products perfectly. Less room in the box for movement means less room for damage.

This is especially important when measuring e-flute boxes as external dimensions include the thickness of the material. At 1/16″ thick, even one layer of material could be the difference between fitting and not.

If a customer supplies you with dimensions, make sure you ask whether they’re internal or external dimensions.